Ceramic Injection Molding (CIM) has emerged as a game-changing technology for producing complex, high-precision ceramic components with exceptional efficiency. Blending the versatility of plastic injection molding with the strength and durability of technical ceramics, CIM offers a manufacturing solution that bridges the gap between performance and scalability. As industries seek smaller, stronger, and more geometrically intricate parts, this process stands out for its ability to deliver just that, without compromising quality or function.

What Exactly Is Ceramic Injection Molding

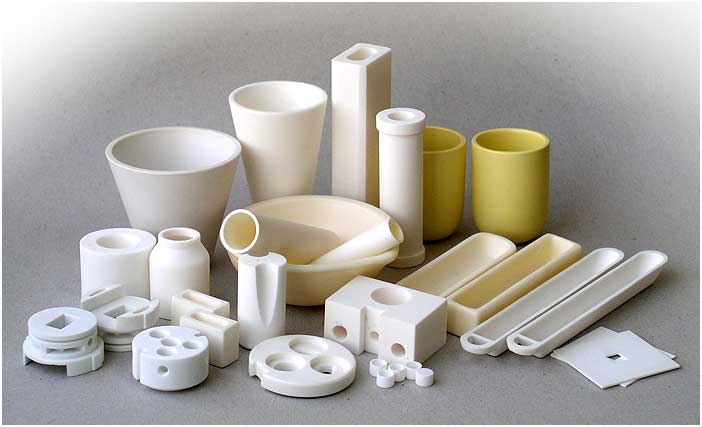

Ceramic Injection Molding is a high-tech manufacturing method that uses injection molding techniques traditionally applied to plastics but adapted for ceramic powders. These powders are mixed with a thermoplastic binder to form a feedstock, which is then injected into a mold cavity under heat and pressure. Once cooled and solidified, the molded part undergoes debinding and sintering to remove the binder and densify the ceramic to its final form.

The real magic of CIM lies in its ability to create highly intricate parts that would be difficult – or nearly impossible – to achieve with conventional ceramic fabrication techniques. From medical implants to aerospace components, CIM makes it feasible to mass-produce precision ceramic parts with consistent dimensional accuracy, high mechanical strength, and resistance to wear, corrosion, and extreme temperatures.

A Sophisticated Process with High Tolerance for Detail

Before the final product even begins to take shape, the ceramic powder must be carefully formulated and mixed with a binder system. This step is crucial, as the right balance determines the ease of injection and the integrity of the final part. Once the mix is ready, it’s molded into shape using advanced injection equipment. The resulting “green part” holds its form but is still fragile. Debinding removes the binder using a chemical or thermal process, followed by sintering, which fuses the ceramic particles together at high temperatures.

The process demands precision at every stage. Even the smallest errors in temperature control or material ratios can lead to defects like warping, porosity, or inconsistent density. Yet, when done correctly, the results are outstanding. CIM parts can have tolerances as tight as ±0.3%, which is why the process is favored for components in sectors like electronics, automotive, medical devices, and telecommunications.

Real-World Applications That Push Limits

CIM’s reach spans a surprising number of industries. In the medical field, it’s used to create tiny, biocompatible components for surgical tools, dental implants, and endoscopic equipment. In electronics, CIM facilitates the production of insulators, sensor housings, and antenna supports, thanks to ceramics’ inherent resistance to electrical conductivity.

In defense and aerospace, high-performance ceramics produced through injection molding withstand high stress and extreme temperatures, offering reliability where it’s needed most. Even luxury consumer goods, like high-end watches and knives, utilize CIM to achieve elegant finishes and precision aesthetics with ceramic’s scratch resistance and hardness.

The Importance of Project Controls in Manufacturing Success

Managing projects that rely on precision manufacturing like ceramic injection molding requires more than technical expertise, it calls for a structured approach to planning, risk management, and quality control. That’s where project controls come into play. These controls form the backbone of efficient project delivery by integrating cost management, schedule tracking, identifying scheduling risks, risk assessment, and change management into a unified strategy. With real-time data analysis and forecasting tools, teams are able to proactively identify issues before they escalate, optimize resource allocation, and maintain alignment with project goals. This disciplined oversight not only ensures that technical specifications are met, but it also helps mitigate budget overruns and delays, which can be especially critical when working with expensive materials and high-precision components. In fast-paced, high-stakes environments, robust project control systems can mean the difference between a flawless product launch and a costly production setback.

Did you know that some of the toughest ceramic materials used in CIM, like zirconia, are nearly as hard as diamonds? That’s one reason why ceramic knives stay sharp longer than steel ones – and why ceramics are increasingly being used in protective armor and even spacecraft components.

Future Potential and Evolving Frontiers

As industries lean toward miniaturization and higher performance, the demand for ceramic components will only increase. Advances in feedstock development, 3D mold designs, and sintering technologies are already paving the way for even more complex and functional ceramic parts. Additive manufacturing may eventually integrate with CIM to further revolutionize prototyping and small-batch production.

In short, Ceramic Injection Molding is not just a niche manufacturing process, it’s a technological powerhouse poised to shape the future of precision components across an astonishing range of industries.